Build for the Future With SIPS & Quit Stick-ing in the Past

In a world where technological advancements have propelled industries forward, construction remains stagnant, entrenched in..

SIPs can be a major structural component of the overall structural system of a building. Since SIPs are recognized on a limited basis by the IRC it is important to make sure your SIP supplier has a code report that was developed by an approved listing agency. The listing agency’s report helps demonstrate code compliance to building officials and design professionals.

Audubon Visitors Center (ND), Premier SIPs

Audubon Visitors Center (ND), Premier SIPs

Here are some important factors to consider and questions to ask when considering various SIP suppliers and their available code reports:

1. Do you have references I could contact?

During your research, ask both building owners and builders about their experiences with the SIP manufactures you are considering. If you don’t know of anyone who has used SIPs before then ask the manufacturer for references for installers, builders, or design professionals. You can even visit a local job site to see SIPs in action. It’s very important to choose a SIP manufacturer who will work with you to identify potential cost savings, early in the design process, and stand behind the product after it’s been delivered. The value you will receive by working with an experienced SIP supplier will save you valuable time and money on the job site.

Amavi Winery (WA), Premier SIPs

Amavi Winery (WA), Premier SIPs

2. Do you have an up-to-date code report?

Without a current code report your local building department may not allow construction to continue, or they may require additional structure to be added to your project. A code report ensures that the SIPs are manufactured and third party tested to verify that they can support the loads that will be applied over the lifetime of the structure. Ask to see a Code Report and engineering design manual with axial, transverse and diaphragm data. An engineer will require this information to design a SIP structure.

3. Are you compliant with the building code required for your project?

Check to see what your building department requires in your area. If a SIP supplier doesn’t meet this specification then there is a good possibility that the building department won’t allow the use of that material.

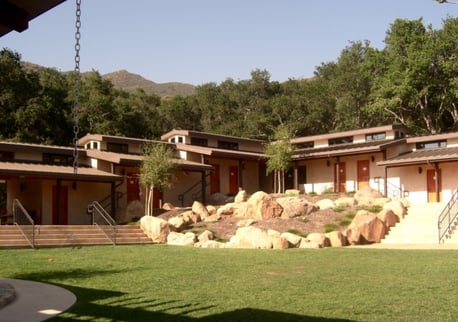

Thatcher School (CA), Premier SIPs

Thatcher School (CA), Premier SIPs

4. Can your SIPs be used in Seismic zone “D” areas (if applicable)?

Check to make sure the SIPs you are looking at using can be used as shear walls in Seismic Zones D, E and F. If not, stick framed shear walls will be required.

5. Will the SIPs have a continuous insulated foam core with minimal lumber?

Installing lumber within the panels will increase the structural capacity of the SIPs. If the testing data is limited or unavailable, some manufacturers' code reports will require double 2x lumber to be installed 4′ on center. This is equivalent to building a stick frame wall with studs 24″ on center. Most manufacturers don’t supply lumber so this can be a significant increase in material costs, decrease the energy efficiency of the building, and increase panel installation labor. This is an important point to consider because the estimate that SIP suppliers will present may not label what type of panels will be required and it’s possible that you will have to supply additional lumber for the panels.

Scammon Bay School (AK), Premier SIPs

Scammon Bay School (AK), Premier SIPs

6. How long do you warranty R-Value and Lamination?

Not all foam cores will maintain the same R-value over the life of the structure. The two most popular SIP cores are Polyurethane and EPS. Polyurethane panel cores will “off-gas” and the R-value will degrade over time. Usually, the R-value that the manufacturer publishes is the optimal R-value right after manufacture. Find out what the R-value will become several years down the road, and what R-value is referenced in the panel warranty. EPS panel cores will not off-gas and decrease R-value over time, but they will probably have lower published R-values than polyurethane. SIP thickness can be increased to meet whatever R-value you require. For more on R-values and energy efficiency see R Values & U-Factors document.

7. Does your code report provide testing data for SIP headers?

Loft at McKinley (AZ), Premier SIPs

Loft at McKinley (AZ), Premier SIPs

If testing hasn’t been performed on the SIPs with window and door openings then you’ll be required by the building code to install lumber headers above the openings. This will require multiple pieces of lumber to be installed from the top of the wall to the foundation to support those headers. If your SIP manufacturer has header testing, then they can often provide a continuous panel with a hole cut out for the opening. This significantly reduces lumber installation and thermal bridging.

8. Do you pre-fabricate the SIPs?

One of the largest advantages to SIP buildings is how quickly they can be assembled. SIP suppliers who have CNC equipment to cut the panels according to your floor plans will be far more accurate and efficient than cutting panels to fit in the field. Check to see if the SIP manufacturer has the ability to create a 3D computer model of your structure. This will help ensure that the angles and cuts will be manufactured accurately.

Rocky Peak Village (CO), Premier SIPs

Rocky Peak Village (CO), Premier SIPs

9. Do you have testing for all thicknesses and sizes of SIPs?

Make sure that the SIP manufacturer’s code report supports the thickness of the panels that you require. If not you’ll end up installing lumber within the panels equivalent to what would be required with a stick frame system. What’s the point of going with SIPs if you need to use as much lumber as you would in a stick frame structure?

10. Can you manufacture up to 8’x24′ “Jumbo” panels?

Bigger = Quicker and more energy efficient. Larger panels can be more difficult to maneuver on the job site, but they are a lot quicker to install. Perhaps the most time-consuming factor in installing SIPs is not erecting the panels, but the labor required to install the mastic sealant on the seams and nailing panel splines together around the entire perimeter of the panels. Consider the seams and labor for:

– 192 square feet of (1) 8×24 panel with 64′ of panel perimeter and 128 nails

– 192 square feet of (6) 4×8 panels with 144′ of panel perimeter and 288 nails

Premier SIPS Resources

Premier SIPS Technical Bulletins & Construction Details

Premier SIPS Builder Resources & Code Reports

In a world where technological advancements have propelled industries forward, construction remains stagnant, entrenched in..

Discover how Premier SIPS' commitment to sustainability and innovation has earned us prestigious industry awards for our..

Discover the key reasons why SIPs offer faster installation and substantial time and labor savings compared to traditional..

As the oldest manufacturer in the SIPs industry, Premier’s SIP system is the proven prefabricated building envelope framing system for your next commercial or residential structure. Faster, stronger, and greener than outdated lumber framing methods, SIPs are the future of framing. Join the other thousands of structures built with SIPs, and contact the expert in your local region to get started.