Build for the Future With SIPS & Quit Stick-ing in the Past

In a world where technological advancements have propelled industries forward, construction remains stagnant, entrenched in..

When you strip down the walls, roof and floors of a building there is a simple and sexy story about how the building envelope that surround us tick. At least us building science junkies think its sexy! Imagine building a structure that you KNOW will operate for a fraction of the energy costs. Is it possible? Absolutely. So why wouldn’t builders and architects look to science to do this?

A quick glance of the science behind building construction and it’s easy to understand how the roofs, walls and floors of our buildings dictate the amount of energy we use to heat and cool the structures we work, shop, dine and live in.

The science behind energy efficiency in our building walls, strips down simply into three areas:

1. Air Transfer/ Airtightness

2. Convective Looping

3. Thermal Bridging

One of the easiest ways to understand these three areas is to look at two side by side wall systems. One built from a conventional stick framed building, alongside one built with an advanced building product like SIPS (Structural Insulated Panels).

Science behind energy efficiency Part #1: Air Transfer/ Airtightness

SIPS, Air Transfer

SIPS, Air Transfer

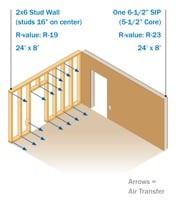

A SIP System is made of LARGE panels (up to 8 ft by 24 ft). Air leakage is responsible for 40% of heat/cooling loss and in building construction. A huge number. Air leaks through joints in sheathing and the inevitable gaps between lumber connections, and between wood framing and insulation. As shown in the illustration below, the arrows in the stud wall show the gaps and connections where air can transfer through the wall. The SIPS wall on the right side of the illustration dramatically reduce air transfer within walls and roofs by minimizing these joints and providing solid, continuous insulation across each panel’s height, width and depth.

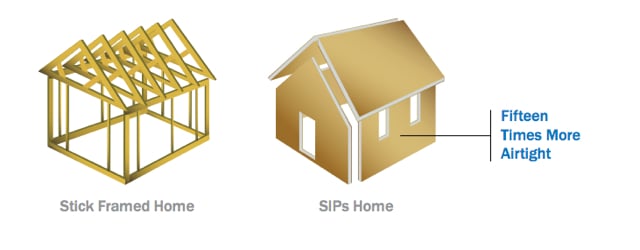

Simple huh? Blower door tests in projects all over the country have confirmed the airtightness in SIPS, further showing how SIP buildings are better at keeping the hot/cold air just where you want it. One impressive study at the Dept of Energy’s Oak Ridge National Laboratory had two identical test rooms built side by side: one stick-framed, one SIP-framed. Rooms were tested for air infiltration and the SIPS room was FIFTEEN times more airtight and more energy-efficient then the stick-framed room. Used in commercial buildings or residential, the air tightness factor is the same.

Science behind energy efficiency part #2: Convective Looping

Not only are SIPS more airtight but the fact that they are manufactured with a SOLID engineered rigid insulated core (not batt fiberglass with gaps throughout) is the part that some might think is the scientifically sexy part of the system.

Inside our walls as warm air rises and cold air sinks in a conventionally framed wall cavity (the inside of the wall) a natural phenomenon called thermal or convective looping occurs, wasting valuable energy. Air is heated or cooled and then it naturally does the opposite as it rises and falls. Talk about a waste.

Check out this illustration to visually see what this means for the stick framed wall:

When a building is insulated with a solid core to stop this air movement, it doesn’t matter what an insulation’s insulating (R-Value) is. What good is insulation if heat-carrying air can flow through it and the cavities in the wall? SIPS solid insulation core helps eliminate this.

Science behind energy efficiency part #3: Thermal Bridging

Rounding up the factors that dictate how efficient our buildings are is one of the most sexy terms out there… thermal bridging. It sounds scientific and complicated but its pretty darn simple.

Basically thermal bridging occurs where there is a continuous element between the cold and warm faces (between the inside and outside) of a wall. This could be wood studs within traditionally framed walls, or simply stud to stud connections where wood touches wood within a wall. These wood elements form a bridge between the inside and outside that can allow heat or cold to pass through by thermal conduction.

Because of factors like thermal bridging, simply installing R-19 batt insulation in a stick wall doesn’t mean the whole wall will have a R-19 R-value because there is still a significant amount of thermal bridging in traditionally framed walls that rely on lumber at regular intervals to provide support. 15-25% of the shell of a stick-framed building is lumber, compared to as little as 3% in the shell of a typical SIPS framed structure.

Another visual to illustrate this is through infrared photography. The picture at the top is stick walls that shows the transfer of heat through the lumber studs (indicated in yellow). The picture at the bottom is of a SIPS framed home, showing that SIPS structures dramatically reduce thermal bridging as shown with solid green walls.

Since buildings consume 80% of our energy it makes sense that we would want to try to reduce fuel and energy we require to heat and cool our built environments… not to mention send less junk back into our environment. One way to use less energy is to build smarter. Building with sticks and dimensional lumber is tried and true, but it really isn’t cutting the bill when it comes to energy efficiency. Time to look to future in how we build… and to build smart and sexy with science in mind.

Visit our website to see how you can use SIPS in your next project….and keep it SEXY!

In a world where technological advancements have propelled industries forward, construction remains stagnant, entrenched in..

When it comes to utilizing Structural Insulated Panels (SIPS) in your projects, there are key considerations that can..

Discover how Premier SIPS' commitment to sustainability and innovation has earned us prestigious industry awards for our..

As the oldest manufacturer in the SIPs industry, Premier’s SIP system is the proven prefabricated building envelope framing system for your next commercial or residential structure. Faster, stronger, and greener than outdated lumber framing methods, SIPs are the future of framing. Join the other thousands of structures built with SIPs, and contact the expert in your local region to get started.