Building Envelope Summit: Seattle & Nor. California Locations

The Summit focuses on the most important assembly in every structure - the envelope. 4/29 in Seattle, WA & 5/1 in Nor...

An airtight building minimizes air leakage, reducing the exchange of indoor and outdoor air. This helps to maintain a more stable indoor temperature, reducing the need for larger heating or cooling systems. As a result, the building becomes more energy-efficient, leading to lower energy consumption and reduced utility costs.

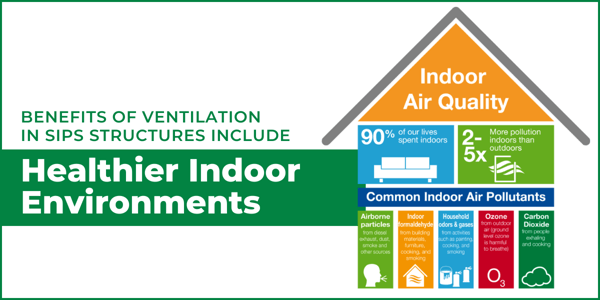

Airtight structures also offer greater thermal comfort, indoor air quality, and noise reduction, and many building codes now include provisions for airtightness as a part of energy conservation.

Structural insulated panels (SIPs) are one of the most efficient ways to create a tight, energy-efficient building envelope for commercial and residential structures. A SIPs building manages airflow, rather than airflow managing the building.

By incorporating continuous insulation (the solid insulation core meets CI building code requirements) and ensuring tight joint connections, SIP buildings minimize the potential for air leaks. As a result, they’re 15 times more airtight than stick framing with fiberglass batt insulation..png?width=600&height=300&name=1%20(1).png)

Building a structure that is airtight and letting the mechanical systems regulate energy use and airflow is key. In ultra-tight SIP buildings, proper mechanical ventilation is required to create a safe, comfortable, and healthy environment for building occupants.

Understanding the proper sealing and ventilation requirements for SIP structures is imperative to create a highly efficient and comfortable building. Learn more about the benefits of property sealing and ventilating an airtight SIPs structure below.

If you can control hot and cold air (heat) mechanically, you can create a more energy-efficient building that consumes and emits 40-60% fewer carbon emissions — and beyond!

With their inherent airtight benefits, many Premier SIPS projects achieve net zero energy status. Many projects are also considered positive energy, meaning the building is so efficient that it generates enough renewable energy to power itself, as well as neighboring structures.

Hot and cold air carries moisture in them. The less uncontrolled moisture coming in through cracks, or flowing within wall cavities, the less chance there is for interior mold and mildew growth. Moisture and water infiltration are some of the biggest builder call-back issues after a building is complete, and reducing these issues saves time and money for builders.

Sealed joints mean fewer places for exterior pollutants, including airborne contaminants, forest fire smoke, diseases, and more, to enter an interior environment.

After living through a pandemic fueled by airborne transmission, and with more than 34 million Americans living with chronic lung diseases like asthma and chronic obstructive pulmonary disease (COPD), the benefit of a super-sealed building envelope is a far healthier indoor environment. Additionally, SIPs are Indoor Air Gold certified in many building applications.

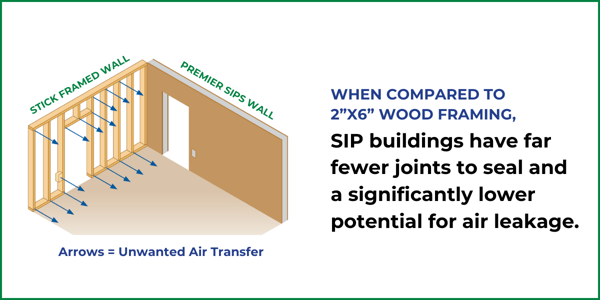

Traditional stick construction, with studs, joists, and numerous other framing members, literally has thousands of joints and connections and is notoriously difficult to seal. On the other hand, SIPs are factory-manufactured in large units comprised of oriented strand board (OSB) and solid expanded polystyrene (EPS) rigid insulation, which results in far fewer gaps to seal.

The Building Science Corporation explains, “Both OSB and EPS foam are air impermeable so there is no air leakage through the center of the SIP panels.”

SIPs are built-to-order in an offsite factory-controlled setting. Large panels can be produced without any joints up to 24’x8’ in size. Manufactured panels are delivered to the job site ready to assemble, with SIP splines joining panels together where needed to ensure an airtight connection.

Panels are installed in a puzzle-piece style, following provided SIP Layout Drawings to ensure joints are properly connected and sealed. Compared to traditional 2”x6” wood framing, when assembled properly, SIP buildings have far fewer joints to seal and a significantly lower potential for air leakage.

It’s crucial to verify with the SIP manufacturer the specific sealing material types and methods that are advised for your panels. You should also refer to local codes to address any unique regional or project-specific requirements.

Also called mastic, this method is used for sealing foam-to-foam, wood-to-foam, and wood-to-wood interfaces. Polymeric mastics are frequently selected due to their ability to maintain flexibility across various temperature and humidity conditions.

High-expanding foam sealant can be utilized to fill gaps that occur between SIP panels or other structural components. These areas include junctions and hollows at the edges of structural elements and voids.

This method involves the use of wide tape over panel joints and corners.

Buildings that experience high humidity due to features like pools or spas may require a vapor retarder. That said, these projects can often meet the building code requirements for vapor retarders by appropriately applying mastic in the panel joints, using SIP tape, and utilizing the panel itself.

In any case, it’s best to consult the project's mechanical engineer for specific guidance.

In traditional structures, the HVAC system may become strained trying to compensate for energy losses caused by air leaks. However, with higher-performance SIP structures, smaller HVAC systems can effectively supply ample fresh air to occupants.

Selecting a properly sized HVAC system for SIPs is crucial for maximizing energy efficiency.

The Structural Insulated Panel Association (SIPA) explains, “…an oversized HVAC system will fail to reach the steady operating rate the equipment was designed for. Short cycling HVAC equipment will be less energy efficient and require more maintenance than properly sized HVAC equipment.”

Also known as air-to-air heat exchangers, HRVs are used to extract air from high-humidity areas like bathrooms and kitchens. These devices pass the moisture-laden warm air through a core, pre-heating incoming cool, fresh outdoor air while expelling the remaining moisture from the building.

HRVs are commonly specified by design professionals in cold climates where dry outside air is prevalent during winter, such as in the Upper Midwest.

This type of SIP ventilator operates similarly to an HRV but also reduces air moisture levels in high-humidity climates, for example, in regions like the Pacific Northwest and Gulf Coast.

Ventilating windows, often found in residential applications, rely on manual operation and incorporate a grille for both air exhaust and replacement. While they do not condition air for heat or humidity, they can provide fresh air in SIP homes.

However, it's important to note that ventilating windows can counteract the benefits of a well-insulated building envelope since they don't manage heat effectively.

Although suitable for certain commercial and residential buildings, these systems should not serve as the sole air management source in SIP structures and other airtight buildings. They rely on air infiltration through the building envelope to replace the vented air, which can lead to negative indoor air pressure in tightly sealed structures.

Rainwater infiltration is the primary cause of premature failure in building enclosures. Like traditional wall and roof assemblies, SIP buildings need to incorporate measures to safeguard against water intrusion.

The International Building Code (IBC) and International Residential Code (IRC) mandate the inclusion of flashing, a water-resistant barrier (WRB), and drainage planes on the exterior to manage any water that enters the envelope. Approved building wraps or liquid-applied membranes can serve as effective WRBs.

An additional protective measure for SIP wall panels is to prevent direct contact between the panels and the concrete foundation wall or floor slabs. This prevents moisture wicking from the concrete into the OSB skins of the panels. Typical construction details for SIP wall-to-foundation and wall-to-slab connections involve incorporating a capillary break on the concrete.

To continue, before installing roofing underlayment, it’s crucial that SIP panels, like traditional OSB-sheathed roofs, are dry. If moisture is present in the OSB, an alternative to using roofing felt is to utilize a synthetic, breathable roofing underlayment, which allows water vapor to pass through while preventing bulk water from moving back toward the SIP panels' OSB.

In addition to safeguarding SIP roof assemblies from water intrusion, specifications should address code requirements for Class A, B, or C fire ratings for roofing placed on a combustible deck, based on ASTM E108 or UL 790 Standard Test Methods. One of the simplest methods to achieve a Class A rating is to include a layer of gypsum board over the SIPs.

As with other aspects of wall and roof assembly design and construction, it’s essential to confirm the requirements with the SIP manufacturer and local codes.

SIP structure ventilation systems and techniques are not unlike those required with other wall and roof systems — the sizing and output requirements may vary, but the concepts remain unchanged. Proper ventilation and attention to building comfort are still paramount for optimal building operation.

For more information about how to ventilate a SIPs house, connect with a Premier SIPS rep in your region.

The Summit focuses on the most important assembly in every structure - the envelope. 4/29 in Seattle, WA & 5/1 in Nor...

In a world where technological advancements have propelled industries forward, construction remains stagnant, entrenched in..

When it comes to utilizing Structural Insulated Panels (SIPS) in your projects, there are key considerations that can..

As the oldest manufacturer in the SIPs industry, Premier’s SIP system is the proven prefabricated building envelope framing system for your next commercial or residential structure. Faster, stronger, and greener than outdated lumber framing methods, SIPs are the future of framing. Join the other thousands of structures built with SIPs, and contact the expert in your local region to get started.