Building Envelope Summit: Seattle & Nor. California Locations

The Summit focuses on the most important assembly in every structure - the envelope. 4/29 in Seattle, WA & 5/1 in Nor...

Project, description/details & photos courtesy of Bruce Hopper, P.E., S.E. | Senior Structural Engineer & BIM Specialist | USKH Inc.

Structural Insulated Panels, SIPs, have been used for many years in many different applications. The following description outlines how Senior Structural Engineer Bruce Hooper, of USKH Inc. in Anchorage Alaska uses Premier SIPs to provide a solution to a rather unique situation.

PROJECT: Quinhagak School | Quinhagak, Alaska

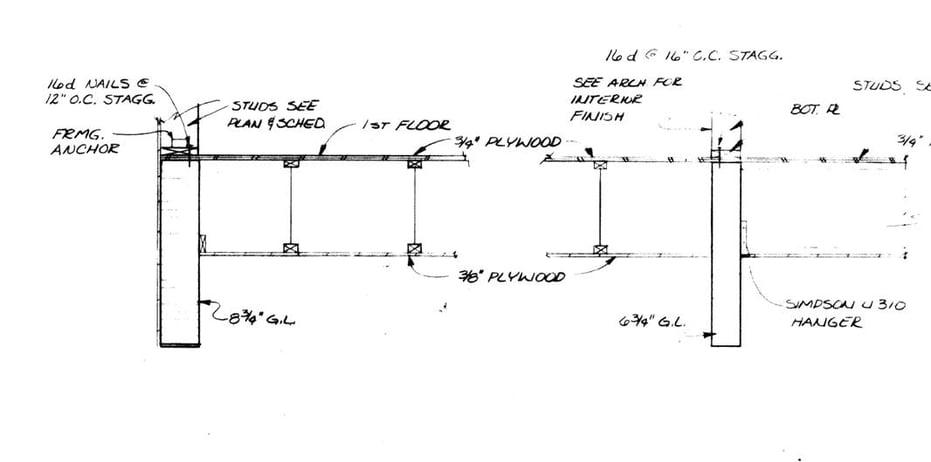

P1: Traditional Floor Assembly

P1: Traditional Floor Assembly

Schools in bush Alaska (rural communities) have traditionally been cold and drafty. Historically, the foundation detail has been as shown as it is to the right (P1). In our application, Premier SIPs are used as a curtain wall system not as a bearing wall.

To understand what we are doing, you have to realize the schools are on permafrost, and then often situated near rivers because the subsistence life style relies on the river for food and transportation. Most of the soils we deal with are fine-grained materials with high percentages of organics, water contents of 40% and frozen at 31.4 degrees Fahrenheit with a thaw point of 31.7 – 31.8 Fahrenheit. To protect the thermal regime in the soil (the soil would collapse if the ice melted), we elevate the buildings on piles so the winter winds blow through underneath. Additionally, the piles are passively refrigerated so they draw heat out of the deep soil during the cold months.

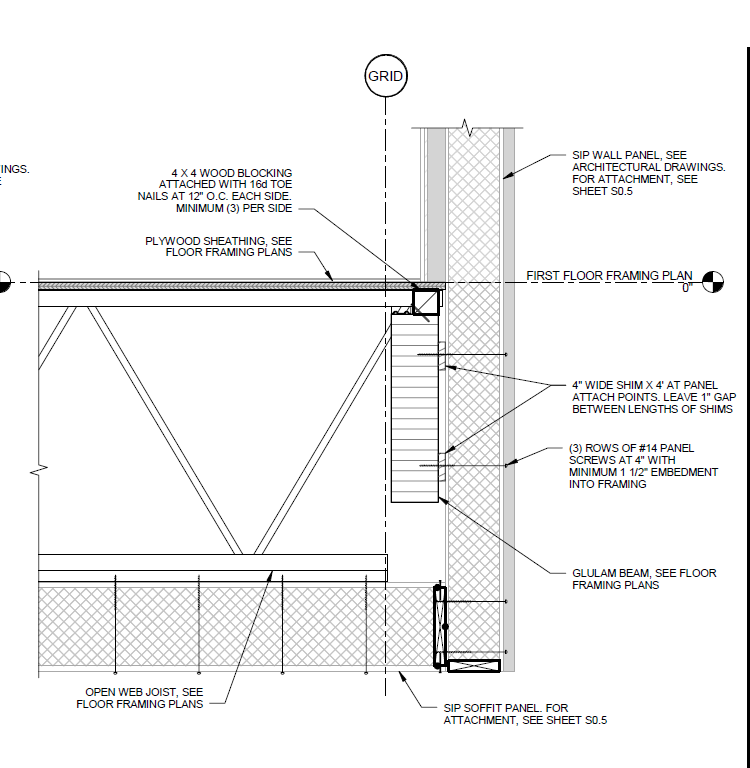

P2: SIPs Details

P2: SIPs Details

As you can see the detail is flawed with numerous places for air infiltration, thru-wood, and a minimal amount of batt insulation. Below floor plumbing is a nightmare because there is no heat circulation. The plumbing freezes, the maintenance man goes out and cuts the plywood out, fixes the pipe, then stuffs in any insulation that may remain (most of it blows away), and re-attaches the plywood. The repair is done haphazardly because he is usually working at sub-zero temps and winds of 15-20 mph.

We have attempted to minimize these problems using Premier SIPs. We create a sub-floor basement using open-web wood chord/steel web trusses. The basement is heated and deep enough to allow maintenance people to crawl around. We have unit heaters in the basement space to keep warm air circulating. The result is comfortable floors and fewer plumbing problems.

Fewer joints between plywood panels means less air infiltration. The joints between the panels get a far better seal than joints in plywood ever would have. Details show above (P2).

The panels are supported by the fasteners into the foundation beam, and they are stitched to the timber columns every 10 feet.

Quinhagak School in early Feb, 2014 (P3)

P3: Quinhagak construction progress in early February

P3: Quinhagak construction progress in early February

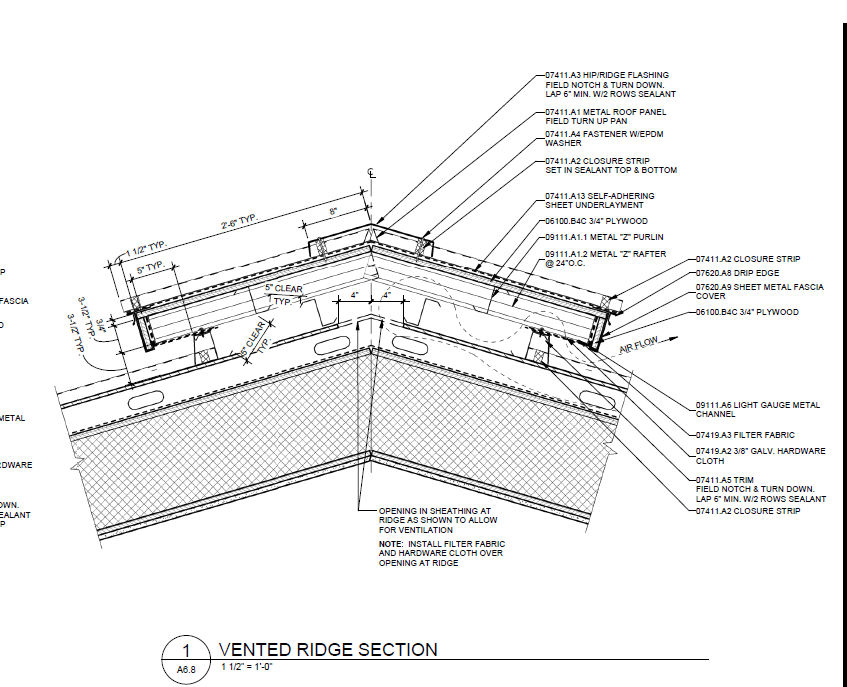

P4: Ventilated Ridge Detail

The roof construction is glulam beams on 10-foot centers, vapor retarder, SIPs, air barrier, metal zee girts, plywood, ice and water shield, and metal deck. We have a ventilated roof system. You can see the Tyvek in the photo above on the upper roof, and the furring system with the ice and water shield on the edge of the lower roof. Left is the ventilated ridge detail (P4)

Additionally, all the wall panels are furred out with a 2 1/2″ insulated stud wall on the interior primarily for electrical runs. The interior furring allows us to create shear walls too since we violate the provisions of ER-1882 without both skins attached to the foundation.

As designed, the system allows the contractor to create an insulated exterior envelope around the project, then construct the mechanical and electrical from within the heated space. The floor can be added after the fact. This contractor elected not to do that. They left the belly open and worked from below.

Quinhagak construction progress (P4, P5, P6, P7)

P4: Quinhagak construction progress

P4: Quinhagak construction progress

P5: Quinhagak construction progress

P6: Quinhagak construction progress

P6: Quinhagak construction progress

P7: Quinhagak construction progress

P7: Quinhagak construction progress

We are striving for an air-tight interior, well-insulated envelope. We believe this system will deliver that. We have heard rumors that on some previous designs we have doubled the square footage of the school and reduced fuel consumption to about half of what they were spending. We want to work with the district when this (and other) school(s) go online to see what their energy costs are. Currently, bulk fuel costs are about $6-$7 per gallon in the bush.

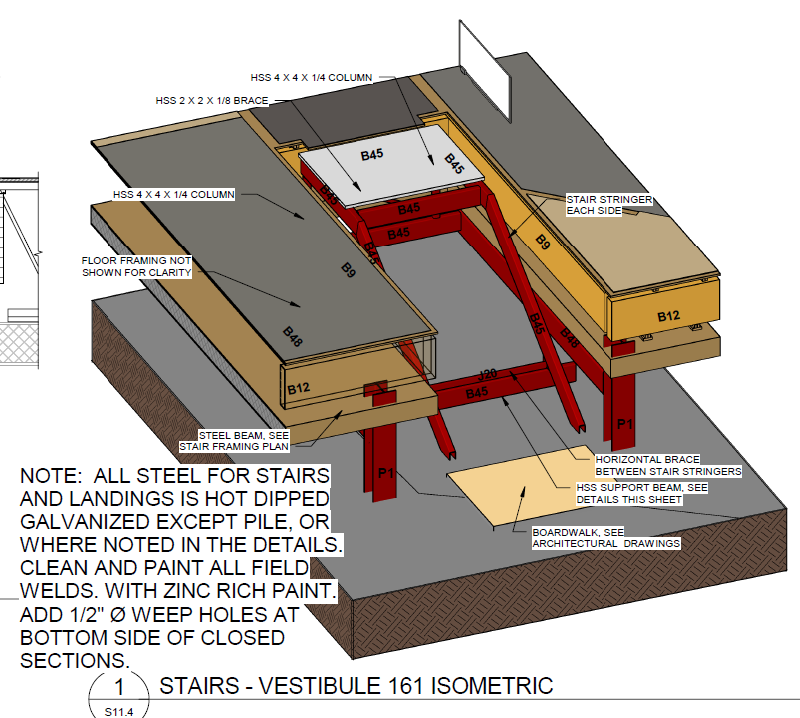

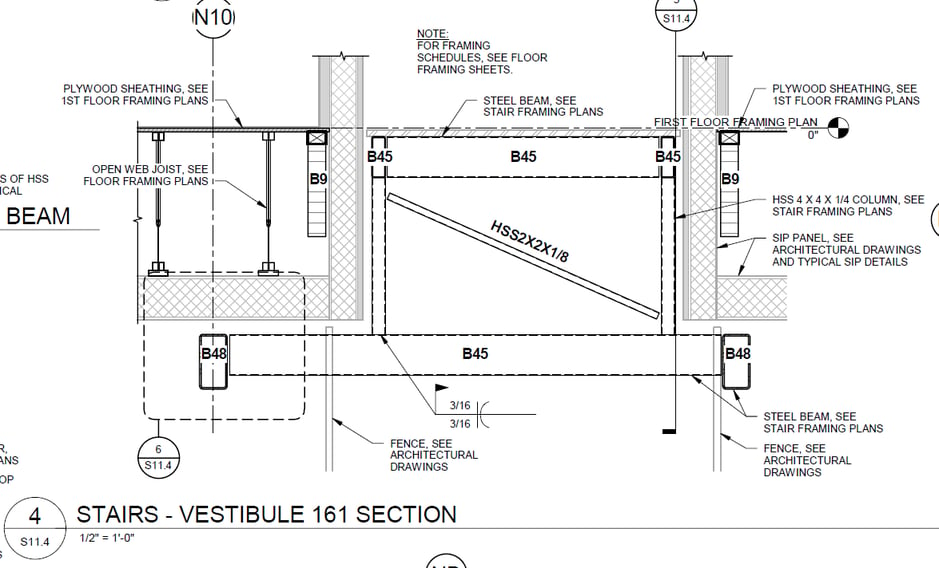

One other feature is that we don’t permit any structure to penetrate the insulated shell. Stairs, decks, and canopies are all supported from outside the structure. The image below shows how the stairs are supported on steel framing attached to the piles below of the soffit SIPs.

Stairs Illustration

Stairs Illustration

Stairs Illustration

“We have been using SIPs in rural Alaska since the early 1990s. We have learned a lot about them and we believe they are doing a great job for us.” -Bruce Hopper

SIP QUESTIONS

Contact Todd Bell,

LEED GA, CSI,CDT, Energy Star Rater

W.Washington & Canada

Regional Sales Manager

Premier SIPS

253-219-9113

Ask Todd to Connect With You on LinkedIn | Follow Premier SIPS on LinkedIn

The Summit focuses on the most important assembly in every structure - the envelope. 4/29 in Seattle, WA & 5/1 in Nor...

In a world where technological advancements have propelled industries forward, construction remains stagnant, entrenched in..

When it comes to utilizing Structural Insulated Panels (SIPS) in your projects, there are key considerations that can..

As the oldest manufacturer in the SIPs industry, Premier’s SIP system is the proven prefabricated building envelope framing system for your next commercial or residential structure. Faster, stronger, and greener than outdated lumber framing methods, SIPs are the future of framing. Join the other thousands of structures built with SIPs, and contact the expert in your local region to get started.